Vortisand® C-Series

SUBMICRON SIDE STREAM FILTRATION FOR COMMERCIAL COOLING LOOPS

REMOVING THE SOURCES OF FOULING TO MAXIMIZE THE EFFICIENCY OF COOLING ASSETS

WHY FILTER YOUR COOLING WATER?

The advantages of side stream filtration include:

- Reduced energy consumption by reducing fouling on heat transfer surfaces

- Improved effectiveness of anti-corrosion and biocide treatment

- Decreased nutrient sources and habitat for potential Legionella growth

- Minimized maintenance and downtime

CHOOSING THE RIGHT FILTER FOR YOUR COOLING APPLICATION

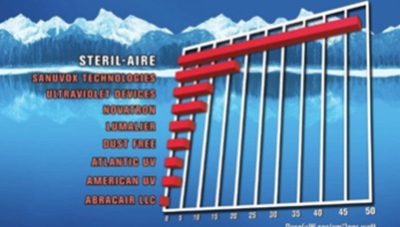

Although many technologies have been used for side stream filtration, for over thirty years Vortisand submicron filters have been recognized as the pinnacle in performance and continued innovation in the industry.

The new C-Series builds on years of experience and customer feedback to provide a range of filters ideal for commercial cooling applications such as HVAC, data centers, central utility plants, hospitals, district energy facilities and many more. Some of the enhancements include:

FEATURES/BENEFITS

Optimized Layout

- 15% smaller footprint

- Simple, intuitive controls for easier operation and troubleshooting

- Piping layout designed for ease of installation and service

- Split skid design for maneuverability in tight spaces such as mechanical utility rooms

Dependable Safety and Reliability

- Dedicated enclosures for high and low voltage electronics to improve safety during operations

- Fail-closed valves to enhance safety and operational integrity

- Pressure vessels built to ASME code for added reliability and longevity

SIZING YOUR SIDE STREAM FILTER FOR OPEN LOOPS

While there are several possible configurations for installing a side stream filter on an open loop. Evoqua recommends the Vortisand filter draw a side stream from the pressurized section of the loop downstream of the main recirculation pumps. This ensures adequate suction pressure to the Vortisand feed pump.

How it Works

FILTRATION MODE:

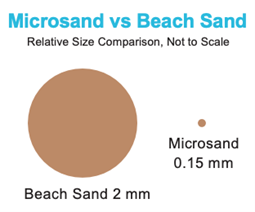

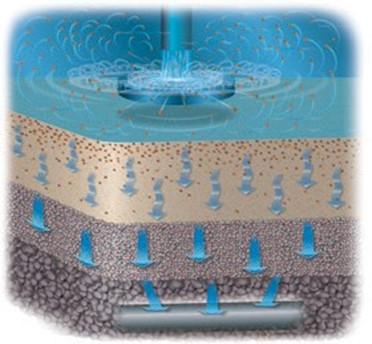

Vortisand® filtration systems use exclusive VortiJet™ diffusers to generate a cross- flow pattern that flows parallel to the surface of the media. Combining this cross-flow pattern with fine 0.15 mm microsand media allows the filter to remove contaminants in two ways: (1) large contaminants are blocked by the microsand while the cross-flow patterns holds them in suspension and prevents them from blocking the surface, (2) finer contaminants that enter the microsand layer are trapped within its fine pores.

- CROSS-FLOW: VortiJet injector induces a cross-flow pattern across surface of media. Large particles are kept in suspension which prevent media surface blinding.1. CROSS-FLOW: VortiJet injector induces a cross-flow pattern across surface of media. Large particles are kept in suspension which prevent media surface blinding.

- MICROSAND: Small particles penetrate the fine microsand media bed where

- SUPPORT STRUCTURE: Larger media is used to act as a support structure for the microsand. These layers do not perform filtration they are trapped within small pores

- UNDERDRAIN: Filtered water flows through the support layers and out through the wedge wire underdrain.

TECHNOLOGY BENEFITS FOR COOLING LOOPSTECHNOLOGY BENEFITS FOR COOLING LOOPS

- Submicron filtration – Removing the fine particles responsible for fouling cooling systems helps to keep cooling equipment operating at peak efficiency.

- Smaller footprint – High filtration rates mean Vortisand filters have the smallest footprint of any media filter.

- Automated operation/minimal maintenance – Vortisand filters are fully automated, require minimal maintenance and have a user-friendly interface complete with maintenance reminders.

- Lower cost of operation – Since the microsand media backwashes easily, Vortisand filters use up to 50% less water for backwashing than conventional media filters.

Recent News

Solving the scale problems associated with Landfills & Wastewater

Landfill Leachate Collection Systems (LCS) can often suffer from excessive scaling and clogging of piping systems, pumps, etc. Conventional remediation methods include expensive hydro-blasting and/or acid cleaning but the problem quickly returns. Problems with scale...

How do you know you are maintaining optimal Air Quality in your Building or Facility?

Air quality in the HVAC systems is an often overlooked problem although it has become more important with concerns about Covid-19 and issues with liability. Biofilm grows in the moist environment of building air conditioning coils. Bacteria, Molds and Viruses can...

A Word About Ionization Systems: DON’T DO IT

Open Letter to address the use of Electronic Air Cleaning Equipment in Buildings by Dr. Marwa Zaatari, Dr. Marcel Harmon Reviewed and supported by: Dr. Linsey Marr, Dr. Jose Luis Jimenez, Dr. William Bahnfleth, Dr. Shelly Miller, Dr. Jeff Siegel, Mr. Hoy Bohanon, Dr....